The relationship with suppliers: from qualification to their monitoring

Qualification

To guarantee a stable and long-lasting relationship with its supply chain, Snam acts ahead of the procurement process, paying a great attention when evaluating the suitability of aspiring suppliers.

The qualification process is aimed at verifying the current capacity of the supplier and its future potential, in accordance with the criteria such as objectivity, transparency and traceability of the evaluations made. There are many factors subject to evaluation: technical and management skills, economic and financial reliability, ethical and reputational risk, commitment to anti-corruption, environmental protection, the promotion of healthy and safe working conditions and the absence of forced labour and economic exploitation of minors. Specifically, there are further requirements for the most critical product categories, such as, for example, a management system certified in accordance with international standards such as ISO 9001 and 14001 and OHSAS 18001.

Throughout the supplier selection and qualification phase, Snam, in line with the Social Supply Chain policy published in 2018, promotes the inclusion of companies belonging to the voluntary sector, such as cooperatives, non-profit companies and associations, incentivising its suppliers to, in turn, adopt similar practices and thereby multiplying the effect. In 2019, new social businesses joined the vendor list and were awarded contracts for the provision of services worth over €300 thousand.

In particular, these social useful players are involved in activities such as gardening services, the digitalization of corporate processes and catering services. Snam, thanks also to the support to external specialized providers, is committed to increase the number of these social useful players to be involved in these activities.

+42% of qualified suppliers in 2019 compared to 2018

In order to ensure the adequacy of the pool of suppliers in terms of current and future procurement needs, Snam is constantly conducting market intelligence research and scouting for new suppliers. The streamlining of procedures carried out in 2019 made it possible to considerably reduce the time needed to complete the entire supplier qualification process. Specifically, during the year, the number of spontaneous applications receiving from aspiring suppliers was 980, 260 of which were contacted regarding approximately 70 different product categories and 110 new applicants were qualified.

At the end of 2019 a total of 2085 suppliers were qualified (+42% compared to 2018) and the qualification of 722 existing suppliers was renewed or newly qualified (+18% compared to 2018).

Performance monitoring

CDP supply chain program

Snam also joined the CDP Supply Chain Programme in 2019 in which 35 strategic suppliers disclosed their data on greenhouse gas emissions (Scope 3 indirect emissions). The CDP will award a score by analysing the data received and this will be the incentive for the management of future environmental impacts.

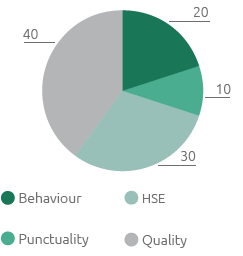

Rating Index -Assessment areas (%)

Snam is committed to involve its suppliers in pursuing its objectives and integrating them in their business model, by constantly monitoring and checking performance and requirements.

The monitoring of performance, inspection visits and evaluation processes, are the main tools used to protect the integrity of the supply chain and to ensure that the expected quality and efficiency standards are maintained. 937 feedbacks were collected during the year (+14% compared to 2018) about the performance of 117 suppliers and 3959 checks on the taxpaying of 1913 suppliers and sub-contractors were carried out (irregularities were detected in the 2,3% of the examined cases).

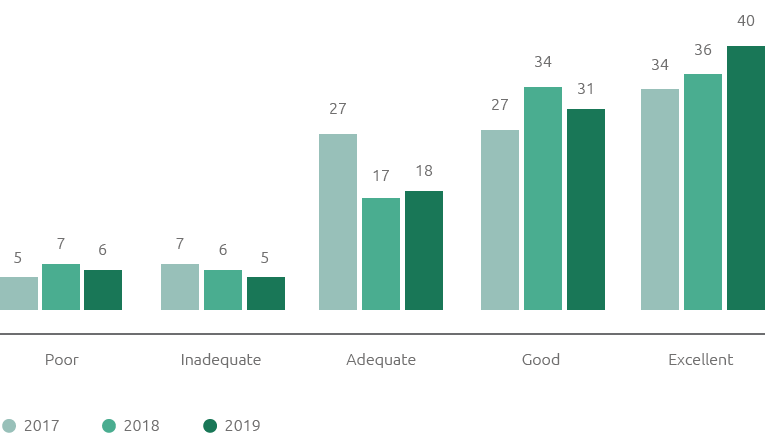

To evaluate the performance of suppliers, Snam uses a rating index (IR) that takes into consideration the compliance to the technical contractual requirements (Quality), the health-safety-environment features (HSE), the agreed delivery times (Level of service) and the ability to establish a good relationship with customers for the entire duration of the contract (behaviour). The evaluation is periodically sent to suppliers in the form of analytical ratings defined on the following evaluation scale: poor, inadequate, adequate, good, excellent. In 2019, the rating “excellent” increased by 4 percentage points, which proves the effectiveness of sharing the Snam’s know-how and best practices along the entire supply chain.

Snam may restrict, suspend or even revoke the qualification of a supplier who fails to meet the agreed standards. Some examples could be a supplier failing to meet the technical-organisational requirements, a negative performance of a supplier or its subcontractors, the non-compliance with the provisions on taxpaying and the rules of the Snam Code of Ethics. In 2019, 41 measures were adopted (+17% compared to 2018).

Supplier performance assessment (%)