Air protection

EN20

The use of natural gas as its principal energy source enables the Company to minimise emissions of sulphur oxides and particulate matter.

Nitrogen oxide (NOx) emissions, the only significant polluting emissions, derive from the use of the gas turbines installed in compression stations (compression and storage) and of the vaporisers at the liquefied natural gas regasification plant.

In order to reduce nitrogen oxide emissions deriving from the combustion of natural gas in the gas turbines used in compression stations, in recent years some existing turbines were modified and new units installed with dry low emission (DLE) combustion systems, while at the regasification plant, submerged flame vaporisers are used.

In 2011, programmes for upgrading station turbines were continued. In particular, a new turbine (TC4) went on line at the Montesano (SA) compression station, and the conversion of the turbine (TC3) at the Fiume Treste (CH) to DLE was completed. The conversion of the turbines at Messina (TC1), Settala (TC1) and Sabbioncello (TC1) to low emissions was begun. In the coming years, these programmes will be implemented predominantly in the storage business.

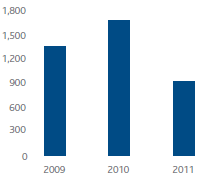

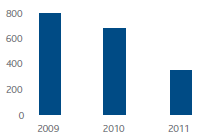

TOTAL NOx EMISSIONS (t)

In 2011, total emissions of nitrogen oxides were around 920 tonnes (-45% compared to 2010). Such a significant reduction in emissions is attributable to lower energy consumption during the year and to the greater number of hours of operation of the DLE turbines compared to the previous year.

NOx emissions into the atmosphere are determined based on direct measurements or, if not available, by emission factors present in the literature (United States Environmental Protection Agency and CORINAIR - COordination INformation AIR project).

| Download XLS (21 kB) |

|

KPI description |

KPI date |

Pre-set target |

Target achieved in 2011 |

Sector |

Activity |

|

No. of DLE turbines |

2010 |

Achieve 75% by 2015 |

67.4 |

Transportation |

|

|

No. of DLE turbines |

2010 |

Achieve 85% by 2015 |

65.2 |

Storage |

|

|

Rated NOx emissions on turbine installed capacity |

2010 |

Achieve 6 mg / (Nm3*MW) by 2015 |

6.6 |

Transportation |

|

|

Rated NOx emissions on turbine installed capacity |

2010 |

Achieve 6 mg / (Nm3*MW) by 2015 |

15.6 |

Storage |

|

|

No. of hours of operation of DLE turbines out of total hours of operation of turbines |

2010 |

Achieve 85% by 2015 |

80 |

Transportation |

|

Waste management

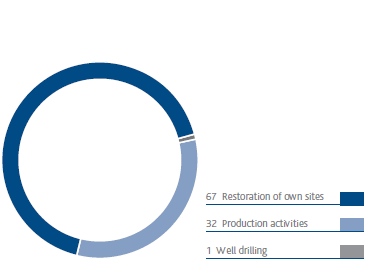

The waste produced by Snam is attributable mainly to three macro activities: production activities, site reclamation and well drilling.

Waste from production activities has always been a relatively insignificant environmental factor in terms of both the quantity and the type of waste. The waste generated derives mainly from the maintenance and management of the plants, and the majority of it consists of ferrous materials which are recovered in full.

Waste from reclamation activities derives from the environmental requalification of some areas contaminated by previous industrial activity. Reclamation waste can also be produced during the laying of pipelines through contaminated sites not owned by Snam in which it must operate.

Waste deriving from well drilling consists mainly of slurries typically produced in some phases of the storage activity.

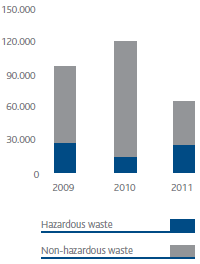

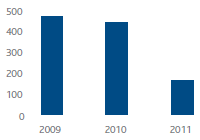

WASTE PRODUCTION (t) |

WASTE PRODUCTION BROKEN DOWN BY ACTIVITY % |

|

|

EN22

In 2011, total waste production stood at approximately 66,070 tonnes, down 45% from 2010. The decrease in waste produced is attributable mainly to extraordinary activity carried out in 2010, which saw the laying of a pipeline in a national polluted site (SIN) for the connection of a third-party plant, which entailed reclamation and disposal of polluted soil.

Out of total waste produced, 40,467 tonnes belong to the non-hazardous waste category (61% of the total) and 59% of disposed waste from production activities was sent for recovery.

During the course of the year, reclamation activities were continued for the recovery and environmental requalification of 29 areas, with a total buildable area of around 134 hectares, contaminated as a result of earlier industrial activities, mainly due to the production of manufactured gas. The areas include sites for which contamination complaints have been submitted to the authorities in accordance with current legislation and sites where only decommissioned plant structures are present.

With these activities, Snam confirms its commitment to the recovery of abandoned industrial sites, with the objective of returning substantial areas to the local community for new development initiatives, while simultaneously aiming to make the best possible use of them.

EN2

Ecologically

The project “Ecologically” continued successfully. Started in 2010, it includes initiatives aimed at promoting good eco-sustainable practices even in the office, with small daily gestures that help to improve the quality of the surrounding environment.

“Some habits make a difference”, the waste sorting initiative at the San Donato Milanese refreshment stands launched in February 2010, was applied to the Turin site for Italgas, the Crema site for Stogit and the Panigaglia site for GNL Italia during 2011. In 2012, we will seek to extend it to certain operating sites.

“All paper recycled” means making all personnel at all group sites aware of the advantages of using recycled paper and at the same time raising awareness of environmental protection issues.

Use of recycled paper increased from 2010, going from 38% to 54%, allowing the group to save natural resources and contain carbon dioxide emissions.

| Download XLS (17 kB) |

|

Trees (No.) |

Water (litres) |

Electricity (kWh) |

CO2eq (t) |

|

-1,126 |

-32,900,056 |

-367,892 |

-178 |

Water

Water procurement and discharge in the activities of Snam represents a relatively insignificant environmental factor, in terms of both the quantities used and the type of discharges.

EN8

In 2011 approximately 4.35 million cubic metres of water were procured (4 million of sea water and 0.35 million of fresh water). The procurement of sea water remained practically unchanged compared to 2010, while that of fresh water decreased 48% compared to 2010.

EN9

Sea water is used for cooling auxiliary equipment in the LNG regasification plant, and fresh water is used primarily for office activities, firefighting apparatus and the irrigation of green spaces.

EN10

With regard to water discharges, the sea water consumed for cooling is released into the sea as is, without any treatment, while the waste water is channelled into the sewage networks (89% of the total) or discharged, after treatment, into the soil and into surface water bodies (11% of the total).

To control the discharge of domestic waste water, activities continued for the construction of closed-cycle phytopurification plants that make it possible to eliminate this type of discharge: the waste water is treated and completely absorbed by the planted vegetation, after separation of the sedimentable solid material. We are evaluating the possibility of extending this technology, used until now primarily at gas compression stations for transportation, to buildings we own (maintenance centres) where no sewage networks are present. In particular, in 2011, a new plant was installed at the Terracina maintenance centre, and a technical audit of the suitability of another 10 sites is under way.

EN21

In the storage business, in the upstream phase, approximately 2,018 cubic metres of process water were produced. Of this water, about 1,630 cubic metres were reinjected as is, while the rest (about 388 cubic metres) was sent to a purification plant for treatment.

FRESH WATER |

FRESH WATER |

|

|

Management of substances harmful to the ozone layer

EN19

The initiatives in progress concern the monitoring and control of all conditioning plants containing substances harmful to the ozone layer in order to check for any gas leaks into the atmosphere. These substances can be found, in modest quantities, in a limited number of plants, and a programme is under way to replace them with ecological fluids. In 2011, at all Snam plants, a small quantity still remains to be disposed of, amounting to approximately 1,480 kg (-31% compared to 2010).

Restricting noise emissions

SO1

For the restriction of noise emissions, Snam implements a prevention policy which consists of correct plant sizing in the design phase, accompanied by the conducting of a noise impact forecast.

The main sources of noise are the gas compression stations (transportation and storage), generally located in rural areas, the pressure reduction and regulation plants that link pipelines with different operating pressures, and the LNG regasification plant.

The principal control measures adopted include the installation of soundproofed cabins, noise-reducing hoods, low-noise valves, silencers on operating vents, and the burial of pipes.

In 2011, for purposes of mitigating noise emissions from facilities via technological adaptations, actions continued for improving the acoustic soundproofing of plants in the gas transportation and distribution network. In particular, in the transportation network, 45 interventions were carried out on gas pressure reduction and regulation cabins (9 in 2010), in accordance with plans calling for interventions at a total of 120 plants by 2013, while in the distribution network, the monitoring of noise emissions, with consequent managerial and/or plant-related interventions, involved 345 plants.