Health, safety, environment and quality

By adopting a Health, Safety, Environment and Quality Policy, Snam is assuming a specific commitment to civil society by recognising the essential value of the principles of protection and prevention. In terms of health, safety, environment and quality, the organisational structure provides for a distinction between the duties of general management, which are centralised within Snam, and the duties of special management, coordination and support for operating units, which are assigned to the individual companies. In particular, the centralised organisational structures ensure the management of expertise, assist the business units in identifying the most efficient technical and organisational solutions, and define, for all companies, the guidelines, methodologies, standards and operating procedures to be applied. They also take care of the definition, implementation and maintenance of management systems, including by means of technical audits. The operating companies maintain an internal organisational structure which allows them to operate with an adequate level of decision-making autonomy.

Management systems

The Snam Group uses specific certified Management Systems with the objective of overseeing the processes and business activities in accordance with the health and safety of workers, environmental protection and the quality of services offered.

The table below shows the certifications obtained by the various management systems, as well as the laboratory accreditations. In 2013, Snam Rete Gas extended the certification of its Environmental Management System to the entire Company, in accordance with the UN EN ISO 14001 standard. For many years previously, the certification covered the gas compression stations and the pipeline network, and the certification of the Quality Management System, implemented in compliance with the UNI EN ISO 9001:2008 standard, followed for the gas process systems (design, development and centralised management of process systems and remote control for the dispatching and metering of natural gas in the transportation network.

During 2013, new certifications were obtained and all necessary actions, including 300 audits (256 internal audits performed by specially qualified staff and 44 audits performed by external companies), were implemented to retain existing certifications.

| Download XLS (24 kB) |

|

Management systems |

|||

|

|

|

|

|

|

Company |

Coverage certification |

Type of certification |

Year of first certification |

|

Snam |

Company |

BS OHSAS 18001 |

2012 |

|

Snam Rete Gas |

Company |

ISO 14001 |

2013 (certification extended to the whole Company) |

|

Gas process systems |

ISO 9001 |

2013 |

|

|

Infrastructure planning unit |

ISO 9001 |

2011 |

|

|

Company |

BS OHSAS 18001 |

2010 |

|

|

Unit size |

ISO 9001 |

2010 |

|

|

Testing laboratory |

ISO 17025 |

2007 |

|

|

Dispatching centre |

ISO 9001 |

2003 |

|

|

Calibration laboratory |

ISO 17025 |

2002 |

|

|

GNL Italia |

Company |

BS OHSAS 18001 |

2012 |

|

ISO 14001 |

2000 |

||

|

Stogit |

Company |

BS OHSAS 18001 |

2012 |

|

Design and delivery of natural gas metering and accounting |

ISO 9001 |

2008 |

|

|

Company |

ISO 14001 |

2002 |

|

|

Italgas |

Company |

ISO 50001 |

2012 |

|

ISO 14001 |

2001 |

||

|

BS OHSAS 18001 |

2001 |

||

|

ISO 9001 |

1996 |

||

|

Calibration laboratory |

ISO 17025 |

1994 |

|

|

Testing laboratory |

ISO 17025 |

1994 |

|

|

Napoletanagas |

Company |

ISO 14001 |

2003 |

|

BS OHSAS 18001 |

2003 |

||

|

ISO 9001 |

2000 |

||

Health and safety

The protection of health and safety in the workplace is one of Snam’s primary objectives.

In 2013, in addition to the requirements of Legislative Decree 81/08, the “Objective Safety” project, launched at the end of 2010, continued its significant initiatives which aim to act on the culture of the workforce to improve attitudes, behaviour and personal responsibility with regard to health and safety at work.

The “Objective Safety” project was implemented to reduce further the number of workplace incidents and accidents, partly by unifying and improving the best practices developed by the individual companies. The three initiatives known as “Safety Trophy”, “Zero Accidents Prize” and “Safety Walk” are also part of the project. The first two are aimed at encouraging all employees to adopt safe and responsible behaviour, through a points-based competition with non-monetary prizes (the first mainly involves the personnel of outlying operating sites, while the second is aimed at all personnel). The third, “Safety Walk”, launched for the first time in 2011, aims to engage the entire Company in achieving effective workplace safety through meetings between top management and Snam personnel in their operational activities.

Internal communication and training act to consolidate knowledge and reinforce attention on the issue. Specifically, the selected channels for communication are as follows: the intranet portal, displays stationed at all Snam worksites and a newsletter which provides in-depth information on the issues, risks and tools associated with health and safety in the workplace. The news bulletin, produced in hard copy, is distributed to all personnel of the Snam Group.

The measures implemented in recent years have enabled us to obtain good results both at the Group level and for the individual companies, as shown by the trend of accident indicators.

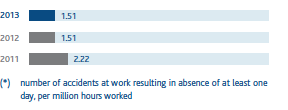

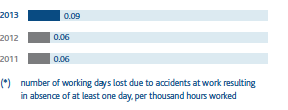

The employee accident frequency index was 1.51 (unchanged from 2012) and the severity index was 0.09 (0.06 in 2012). The increase in the severity index is due to more severe consequences from the accidents that occurred.

ACCIDENTS AT WORK - EMPLOYEE FREQUENCY INDEX(*)

ACCIDENTS AT WORK - EMPLOYEE SEVERITY INDEX(*)

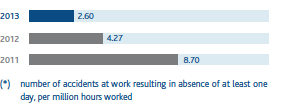

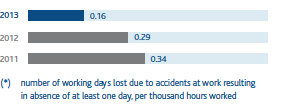

With regard to safety in connection with contracted labour, special attention was paid to suppliers’ qualifications and, subsequently, to evaluating suppliers through special inspections performed in the work execution phase.

We further increased supplier involvement regarding safety aspects by holding specific sessions to help raise the awareness of our suppliers to these issues, partly because of the growing importance of safety indicators within supplier qualification and evaluation criteria.

There were no fatal accidents in 2013.

ACCIDENTS AT WORK - CONTRACTOR FREQUENCY INDEX(*)

ACCIDENTS AT WORK - CONTRACTOR SEVERITY INDEX(*)

During the course of the year, the commitment to protect the health of employees was reaffirmed by focusing on continually monitoring risk factors identified in the corporate processes and implementing suitable prevention and protection measures. Work environment inspections were carried out in order to evaluate adequate and appropriate working and environmental conditions and to identify possible measures for prevention or improvement. A total of 260 environmental inspections were performed in 2013.

Activities continued to support specific health protection initiatives, such as cancer prevention and flu vaccination campaigns, bans on smoking in Company workplaces, and on the supply of alcohol in Company canteens.

We ensure that regular health checks are performed on personnel exposed to specific risk factors, with 2,674 check-ups during the year.

Environmental Protection

Protection of the environment is of primary importance during all phases of Snam operations. The criteria and procedures adopted for the location, design, construction and management of the plants meet high environmental protection requirements.

Snam is committed to providing Italy with a daily source of energy, natural gas, which owing to its chemical and physical properties and its ability to be used in highly efficient technologies in various sectors (civil, industrial and thermoelectric), is able to provide a significant contribution to reducing atmospheric emissions of greenhouse gases (GHG), particles and sulphur oxides. In fact, using the same amount of energy, the carbon dioxide (CO2) generated by natural gas consumption is 25-30% less than that produced by oil products and 40-50% less than coal.

The more significant environmental aspects of Snam operations are the temporary use of the soil during the construction of new transportation infrastructure and the atmospheric emissions from the use of gas turbines installed in the gas compression stations (transportation and storage).

When laying pipelines, the route is selected from a variety of alternatives according to environmental impact, transportation safety and technical and economic feasibility considerations. In particular, it seeks to avoid or to minimise the passage through areas of significant natural or cultural interest, archaeological areas, geologically unstable areas and inhabited areas where the construction of new dwellings is anticipated. When laying the pipelines, technologies are used that interfere with the surrounding environment as little as possible. Having completed the works, a careful environmental restoration operation is carried out to return the land to its original condition.

During the year, environmental restoration activities mainly concerned the regions of Friuli Venezia Giulia and Sicily. Restoration works were carried out, along the paths of the methane pipelines, over a total distance of approximately 131 km, and new trees were planted along 22 km.

During operation, the plants and pipelines periodically undergo inspections and maintenance to ensure very high safety standards. Particular attention is paid to the section of lines that are inspected regularly by vehicles, using helicopters and personnel on foot in order to detect potentially hazardous situations caused, for example, by the works of third parties in the area of the pipelines. Similarly, any land slippage at specific points of the route is also kept under surveillance. The integrity of the pipelines is also inspected by passing devices along them known as “intelligent pigs”, which can detect any faults.

In 2013, around 2,342 km of network were inspected with intelligent pigs and around 15,400 km using helicopters.

The use of natural gas, which meets almost all of Snam’s energy requirements, allows us to minimise sulphur oxides and particle emissions.

To limit the emissions of nitrogen oxides generated by the gas turbines used in the compression stations, specific programmes have been defined over the years to modify the existing turbines and install new units with low emission combustion (DLE) systems in both gas compression stations and storage facilities.

The main activities carried out during the year in the storage facilities were as follows:

- entry into service of the DLE turbocompressors at Cortemaggiore (TC2) and Fiume Treste (TC1);

- upgrading of DLE turbocompressors at Sabbioncello (TC2) and Minerbio (TC4).

The main activities carried out during the year in the compression stations were as follows:

- entry into service of the DLE turbocompressors at Messina (TC1);

- upgrading of the DLE turbocompressors at Messina (TC2).

The greenhouse gases (GHG) emitted into the atmosphere by Snam operations are CO2 and methane (CH4), the primary component of natural gas. The CO2 is a by-product of the combustion process and is directly associated with the consumption of fuels, while the emissions of natural gas, and therefore of CH4, derive partly from the normal operation of the plants and partly from the atmospheric emissions due to the connection of new pipelines and maintenance or to accidental events in the transportation and distribution networks.

Snam seeks to minimise its GHG emissions in its operations by implementing specific containment programmes such as:

- the reduction of natural gas emissions (through the recompression of gas in pipelines, the replacement of pneumatic equipment and the replacement of cast-iron pipes in distribution networks);

- the reduction of power consumption (using specific energy management measures);

- the use of electricity produced from renewable energy sources (through specific purchase contracts and the installation of photovoltaic panels in building construction).

The following Snam facilities are subject to the Emissions Trading Directive (2003/87/EC) that gave rise to the greenhouse gas ‘emissions market’: 11 gas compression stations and 1 entry point terminal at Snam Rete Gas; 7 gas compression stations at Stogit and 1 LNG regasification plant at GNL Italia.

At the start of the third regulatory period (2013-2020), the greenhouse gas emission authorisation system, previously governed by Legislative Decree 216/2006, was updated and modified by Legislative Decree 30 of 13 March 2013, effective from 5 April 2013.

In order to achieve the emission targets set out in the Kyoto Protocol, the Snam Group’s free CO2 quotas are now gradually decreasing, rather than constant as they were in the second regulatory period. Moreover, quota allocations for the third regulatory period also depend on the actual productivity of the plant in the previous year.

In 2013, total CO2 emissions were around 533,000 tonnes. The annual quotas issued by the Ministry of the Environment and the Protection of Land and Sea amounted to around 719,000, meaning a surplus of approximately 186,000 tonnes.