SO9-SO10

When developing new installations, Snam adopts procedures that pass stringent safety and environmental compatibility assessments and satisfy technical and economic feasibility criteria.

Assessments of the effects on the surrounding environment concern all phases of a project’s life cycle: location, design, execution, operation and decommissioning. These assessments are made as part of the Environmental Impact Assessment (EIA), after which the administrations in charge, both centrally and locally, issue the authorisations provided for by current regulations.

When developing the network of gas pipelines, which represents the most recurring and significant event, in the design phase, the path is chosen from among different alternatives, seeking to avoid or minimise the network passing through areas of significant natural or cultural interest, archaeological areas, geologically unstable areas and anthropised areas or those in which new residential settlements are expected.

In the construction phase, in special cases, procedures and technologies are used, consistent with technical feasibility, which reduce interference with the surrounding environment, such as reducing the expanse of the work area, minimising provisional worksite infrastructure and trenchless execution techniques (tunnels and micro tunnels), as alternatives to traditional excavation. Once installation is done, accurate environmental restoration activity is carried out so as to return the land to its original conditions.

In the decommissioning phase, infrastructure is removed by agreement with the relevant authorities. In some cases, in order to safeguard the biodiversity reconstituted thanks to restoration interventions, the possibility of keeping piping underground after it has ceased to be active, thus avoiding additional worksite activities, is evaluated.

EIA DECREES OBTAINED DURING THE YEAR

| Download XLS (15 kB) |

|

Name |

Length (km) |

Regions involved |

Competent agencies |

Date of decree | ||

| ||||||

|

Piombino - Collesalvetti natural gas pipeline |

81 |

Tuscany |

MATTM - MBAC* |

07/09/2012 | ||

|

Increase the maximum operating pressure of the Sergnano concession gas storage deposit to 1.05 times the initial pressure when the field was discovered. |

|

Lombardy |

MATTM |

15/10/2012 | ||

EIA REQUESTS SUBMITTED TO MATTM AND MBAC IN 2012

| Download XLS (16 kB) |

|

Name |

Length (km) |

Regions involved |

Date of submission |

|

Cervignano - Mortara natural gas pipeline |

62 |

Lombardy |

08/08/2012 |

|

Increase the storage capacity by increasing the maximum operating pressure (Pmax) to more than the original static bottom-hole pressure (Pi) of the field (Pmax = 1.10 Pi), and increase the peak withdrawal capacity by building a new treatment plant and drilling four new wells. |

|

Lombardy |

04/10/2012 |

|

Increase the storage capacity by increasing the maximum operating pressure (Pmax) to more than the original static bottom-hole pressure (Pi) of the field (Pmax = 1.07 Pi) |

|

Emilia-Romagna |

21/02/2012 |

EIA DECREES SUBMITTED TO THE REGIONS IN 2012

| Download XLS (15 kB) |

|

Name |

Capacity (MW)-Length (km) |

Regions involved |

Date of submission |

|

Minerbio - Poggio Renatico natural gas pipeline |

21 |

Emilia-Romagna |

02/03/2012 |

|

New compression station at Minerbio |

24 |

Emilia-Romagna |

02/03/2012 |

|

Upgrade of compression station at Poggio Renatico |

25 |

Emilia-Romagna |

02/03/2012 |

REQUESTS FOR VERIFICATION OF REQUIREMENT FOR AN EIA SUBMITTED TO MINISTRY OF THE ENVIRONMENT IN 2012

| Download XLS (16 kB) |

|

Description |

Region |

Date of submission |

|

New gas plant at Bordolano – Modifications to the plant’s equipment and to the lay-out ofthe equipment and buildings of the compression and treatment facilities regarding the configuration which has obtained environment friendly status |

Lombardy |

10/12/12 |

|

Construction/installation of a new turbocharger, the TC-7, at the existing gas storage facility at Concessione Minerbio |

Emilia Romagna |

21/12/12 |

The infrastructure sustainability concept that Snam promotes at all levels also includes socioeconomic evaluations associated with the execution of new works. In 2012, Snam continued on an experimental basis to apply “Social Impact Assessment” tools and methods, which are widely used in other contexts and countries and which make it possible to deal with these issues systematically by specifically evaluating quantitative and “measurable” impacts of an economic, demographic and social nature.

Gas storage and transportation infrastructure development investments directly and indirectly affect regional and municipal economies. Snam has developed experimental Social Impact Assessment methods to evaluate and measure the social and economic impacts of building certain specific infrastructures.

In 2012, and still on an experimental basis, this tool was extended further from a methodological perspective to include the construction of natural gas pipelines, and in terms of economic impacts to include compensation measures as a way of offsetting the environmental impact of certain types of infrastructure.

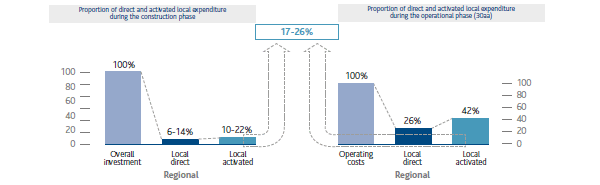

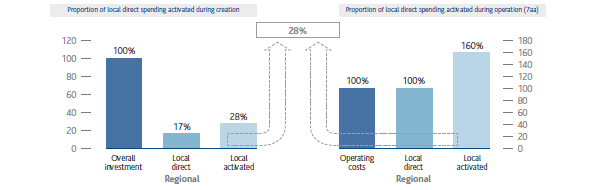

The analyses conducted using Snam’s Social Impact Assessment model show that, in relation to large infrastructure such as compression stations and major pipelines, the impact of Snam’s direct (through its activities) and indirect (through subcontracted activities) investments on the local economy (i.e. municipal, provincial and regional) is, on average, 17-28% of the value of the investment over its lifetime.

EXAMPLE OF ESTIMATE OF DIRECT AND ACTIVATED LOCAL EXPENDITURE DURING THE LIFE CYCLE OF A COMPRESSION STATIONS

EXAMPLE OF ESTIMATE OF DIRECT AND ACTIVATED LOCAL EXPENDITURE DURING THE LIFE CYCLE OF A METHANE PIPELINE*

* Example of a methane pipeline about 150 km long with mountainous/mixed territorial structure

Methodology for analysing economic and social impacts on the local area

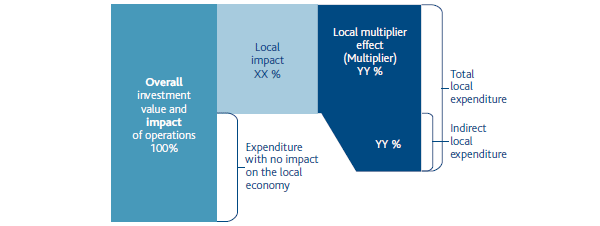

The socioeconomic impact, which as a concept is based on the difference between pre- and post-investment conditions, can be calculated using various models. Given the type of investments made by Snam, the preferred model is one that focuses on the estimated economic effects arising from construction and operating expense. Local expenditure is calculated along a chain which begins with direct spending on construction and operations. A work site, for example, affects local food services, catering suppliers, employees and others further along the chain.

Once the investment and operating components have been identified, multipliers (specific to each sector/product and available from Istat sources) are applied relating to the positive effect of reinvesting capital in the local economy. This multiplier effect turns direct local expenditure into the total local expenditure.