The supply chain

Snam operates in a transparent manner and in full compliance with the spirit of free competition seeking to involve suppliers in reaching long-lasting high performance levels with a view to mutual growth and creation of value.

The Company has been committed for some time to strengthening the culture and good practices surrounding transparency, appropriate relations, workplace safety and protecting the environment. Snam is committed to adopting responsible and sustainable purchase criteria and to optimising the related management processes.

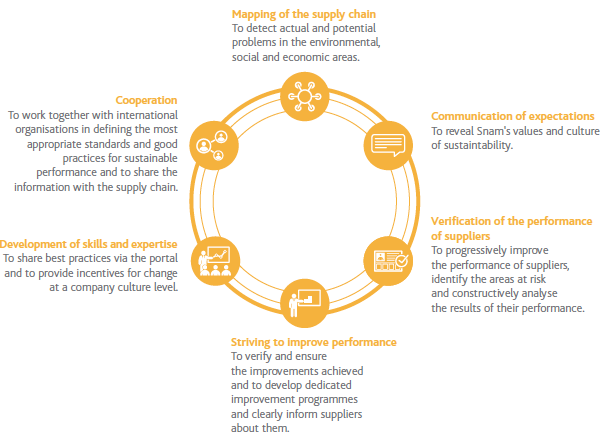

The sustainable management model for suppliers

By revisiting the organisational model the Chief Corporate Services Officer was put in charge of the supply chain function in order to guarantee greater coordination of procurement activities within Snam.

The extended application of strategic sourcing methods will make it possible to achieve cost savings in line with business activities and to maintain an adequate pool of suppliers to manage tenders and planned procurement requirements.

Snam receives around 2,000 applications from potential suppliers every year. All of those who intend to supply goods, works and services to Snam must not only satisfy the requirements of quality, price and reliability, but they must also share the desire for the innovation of processes and the commitment to reduce impacts and risks of an environmental and corporate nature inherent in the chain. This happens through a rigorous and thorough qualification process, the only way in which a supplier candidate comes into contact with Snam to let them know current capacities and future potential ones.

Many elements are subject to evaluation, starting with technical and management capacities to economic and financial reliability, from the ethical profile, including references, to commitment to fighting corruption, safeguarding and protecting the environment, promoting healthy and secure working conditions and the absence of forced labour and the economic exploitation of minors.

An increasingly well-established relationship |

|

Quality |

Not only requirements of quality, price and reliability, but also commitment to process innovation |

Safety |

Dissemination of the culture of prevention and attention to the health and safety of workers |

Values |

Transmission and sharing of values: legality, correctness, transparency and compliance with free competition |

Transparency |

Correctness, traceability and transparency in commercial relations and in exercising activities |

Continuous improvement |

Striving towards continuous improvement, mutual growth and creation of shared value |

Sustainability |

Reduction of impacts and risks of an environmental and social nature inherent in the supply chain |

| Download XLS (18 kB) |

|

Number (1) |

Work practices (2) |

Environmental criteria |

Human rights (3) |

||||||||||||||

|

2014 |

2015 |

2016 |

2014 |

2015 |

2016 |

2014 |

2015 |

2016 |

2014 |

2015 |

2016 |

||||||

|

||||||||||||||||||

Goods |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Qualified suppliers |

1,443 |

850 |

754 |

37% |

43% |

42% |

37% |

43% |

42% |

100% |

100% |

100% |

||||||

of which criticality classes A and B |

204 |

144 |

129 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Suppliers qualified in the year |

129 |

56 |

54 |

25% |

60% |

50% |

25% |

60% |

50% |

100% |

100% |

100% |

||||||

of which criticality classes A and B |

17 |

10 |

7 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Works |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Qualified suppliers |

403 |

353 |

310 |

70% |

70% |

75% |

70% |

70% |

75% |

100% |

100% |

100% |

||||||

of which criticality classes A and B |

82 |

72 |

83 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Suppliers qualified in the year |

101 |

33 |

30 |

74% |

82% |

80% |

74% |

82% |

80% |

100% |

100% |

100% |

||||||

of which criticality classes A and B |

42 |

7 |

9 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Services |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Qualified suppliers |

2,271 |

1,728 |

1,631 |

38% |

33% |

34% |

38% |

33% |

34% |

100% |

100% |

100% |

||||||

of which criticality classes A and B |

153 |

124 |

133 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Suppliers qualified in the year |

389 |

127 |

130 |

29% |

41% |

36% |

29% |

41% |

36% |

100% |

100% |

100% |

||||||

of which criticality classes A and B |

32 |

15 |

10 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

| Download XLS (16 kB) |

Description of KPI |

KPI data |

Pre-set target |

Target reached in 2016 |

Sector |

Activity status |

||

|

|||||||

Number of works suppliers (criticality A and B) with OHSAS 18001 certification |

2014 |

Reach a value of 100% in 2016 |

100 |

Snam Group |

|

||

Digitalised Vendor Management System

Since May all procedures for registering, renewing or extending supplier qualifications have been carried out exclusively online, through a dedicated IT platform. The qualification and performance evaluation process of those working for Snam has been digitalised, with a large number of suppliers (more than 2,200) divided into approximately 650 product categories, which feature multinationals and independent contractors, small and medium enterprises and cooperatives. A system that has brought considerable advantages for the company and its suppliers.

- Efficiency: the process is guided and the system only requires the updating of documents that have expired and obsolete information;

- Security: when a document is uploaded online, it is automatically archived;

- Transparency: the progress of the paperwork is always visible online;

- Service: an integrated messaging service makes it possible to remain in contact with the Company.

Together with suppliers for a culture of sustainability

In 2016 as well Snam met with its suppliers with the aim of creating a shared culture on fundamental issues, such as innovation, sustainability and business ethics.

During the meeting, in which more than 450 people took part, a great deal of attention was paid to the value of collaboration between the company and suppliers as a factor for development, the strategic importance of the sustainable supply chain, the theme of transparency and the fight against corruption.

Specific discussions then touched on more technical subjects, such as: the new procurement code; the environment and innovation (the best practices of foreign investees); innovative technologies in the oil and gas industry; the development of technologies to promote alternative uses of natural gas.

The event was recognised as a training credit by the Milan Order of Engineers.

GRI-G4:12,EN32,EN33,LA14,LA15,HR10,HR11