Supply chain GRI – G4: EN32, EN33, LA14, LA15, HR10, HR11

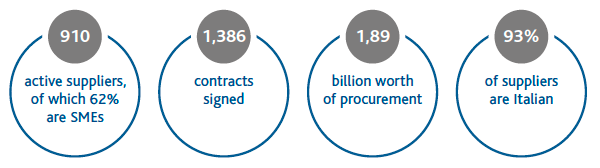

Snam’s 2015 procurement data GRI – G4: 12, EC9

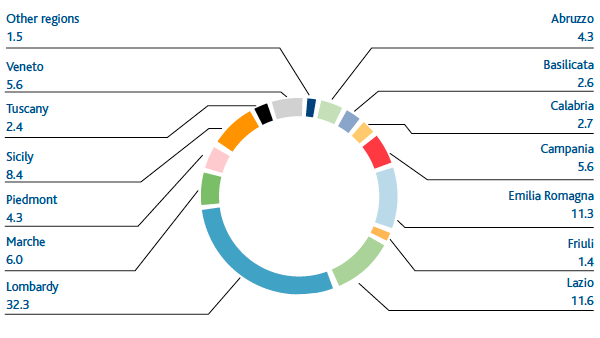

Geographical distribution of Italian procurement (%)

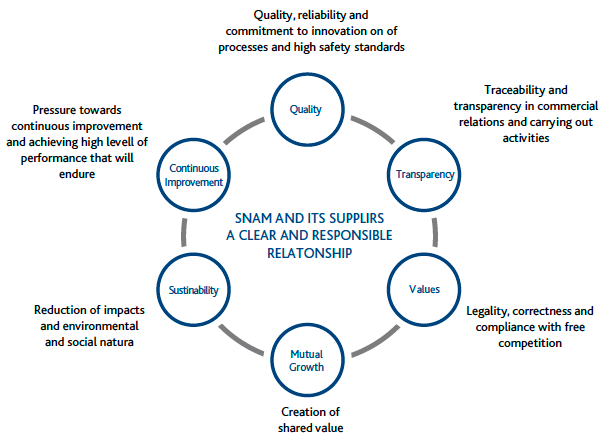

Trust – an essential element of our sustainable development model

Businesses that want to provide goods, works or services to Snam Group companies do not only have to satisfy our quality, price and reliability requirements but also share our passion for innovation and our commitment to reducing social and environmental risks and impact throughout the supply chain, committing themselves to a clear and responsible relationship.

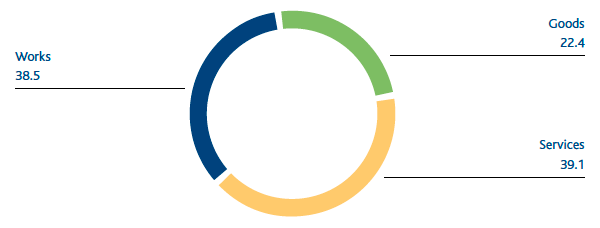

Procurement by type (%)

Phases |

Activities |

2015 data |

Checks during the qualification phase |

Assessment is based on key issues broken down into four different levels (A, B, C, D) allocated to each category of goods depending on technological complexity and impact on Snam’s performance. Many elements are assessed, starting with technical and operational capabilities. We pay particular attention to the candidate’s financial reliability and to their commitment to workplace health and safety and environmental protection. We have further requirements relating to the most critical categories of goods (A and B), such as possessing management systems that have been certified in accordance with international standards. |

We audited 19 key suppliers at the qualification stage 295 suppliers were subject to renewals and new allocations As at 31 December 2015, there were 2,547 suppliers on the vendor list. |

Service monitoring during the contract execution phase |

Monitoring includes audits, inspections and assessments of services with the help of the teams responsible for managing the contracts. |

We got 1,300 pieces of feedback from 243 suppliers We performed 6,750 checks on 1,862 suppliers and subcontractors as to the regularity of their social security contributions, uncovering 308 irregularities (4.6%). |

Performance evaluation |

Snam uses a ratings index that assess compliance with technical and HSE contractual requirements (Quality), compliance with delivery deadlines (Punctuality) and relations for the duration of the contract (Conduct). We periodically send our evaluation to the suppliers in the form of analysis. Snam is entitled to limit, suspend or revoke the qualification of any supplier that falls short of the agreed standards. This may occur in the event of failure to meet technical and organisational requirements, a negative evaluation of services provided by the supplier or its subcontractors, or failure to comply with measures regarding social security contributions or rules in Snam’s Code of Ethics. Suppliers who manage to complete their gas infrastructure construction or maintenance work with no accidents will be rewarded in their score. |

There were 92 instances of non-compliance, for which we issued warnings, suspensions or revocations. |

The Supplier Portal – transparent and efficient

Snam’s Supplier Portal, the online platform that has quickly become the main instrument through which suppliers can get in touch with Snam, has been active since 2013. The portal is at the heart of Snam’s procurement policy, enhancing the daily operations of all those involved in managing the entire supply chain. It contains information, analysis, best practice (for example on employee health and safety, human rights and respect for the environment), documents, updates on supplier qualification procedures, tenders and access to e-business. It also contains the most important data and indicators on Snam’s procurement, helping to make information more complete and transparent. At present, around 1,500 suppliers are registered to the portal, up 50% on the previous year, and each of them has a private area through which they can access information on the segments for which they are qualified suppliers, their current agreements, workplace safety performance, administrative items and forms. We made additions to the various sections of the portal in 2015 to improve the levels of dialogue and knowledge sharing with our suppliers. More than 89,000 people (+7% on 2014) visited the portal in 2015, accessing it over 234,000 times (+5%).

Annual workshop for strengthening Company-supplier relations

Snam once again held its annual workshop for suppliers, giving it a chance to talk with its suppliers, consolidate quality standards throughout the supply chain and share its model of sustainable growth.

We discussed topics such as high-quality and transparent relations with suppliers, sustainability and shared value as a lever for responsible corporate growth, and the importance of quality, safety and environmental certification with regard to reputation and competitiveness. We focused, in particular, on workplace safety and the high standards of environmental protection to which the Group and its suppliers are asked to adhere. Dedicated working groups tackled subjects like the Ethics and Integrity Agreement with suppliers, the subcontractor management system, the supplier qualification and assessment system, the eco-friendly and sustainable solutions for constructing and maintaining buildings and plants, enterprise risk management, and safety at Snam Rete Gas construction sites and Stogit and GNL Italia facilities. Another working group was dedicated to presenting Italgas’s new model for managing construction site activity. Going forward, these initiatives represent the basis on which Snam will ensure quality, transparency and cooperation in its relationships with the supply chain – crucial elements for the growth of the Group as a whole and for the entire community.

All A and B suppliers in the “Works” category have ISO 9001 and ISO 14001 certified quality and environmental management systems, while 95% have OHSAS 18001 certification (employee health and safety). We aim to get this second percentage up to 100% by the end of 2016.

| Download XLS (29 kB) |

KPI description |

Date of KPI |

Target |

Result 2015 |

Segment |

Status of activity |

Portion of A and B “Works” suppliers that are OHSAS 18001 certified |

2014 |

Reach 90% by 2015 |

95 |

Snam Group |

|

|

|

||||

| Download XLS (22 kB) |

|

2014 |

2015 |

Total number of disputes outstanding at end of year |

22 |

23 |

Disputes entered into during the year |

7 |

8 |

Disputes resolved during the year |

16 |

13 |

Supplier due diligence

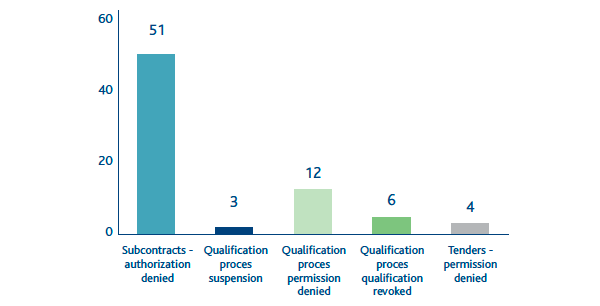

In 2015, more than 2,000 reputational checks were carried out on suppliers, subcontractors and potential suppliers of the Snam Group. The checks covered: subcontract authorizations (1,083), supplier qualification processes (1,000) and participation in calls to tender (79).

The checks revealed 461 reputational alerts. As a result of the checks carried out on reputational alerts by the assessment team, 76 disciplinary measures were adopted.

Reputational checks

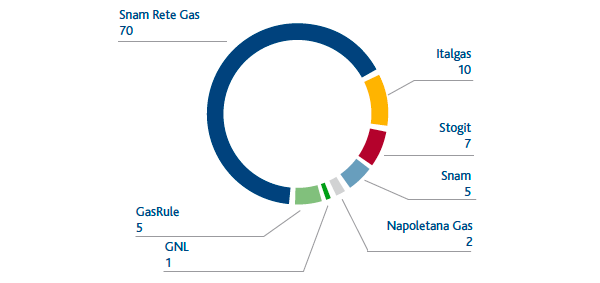

Break-down by Group Company (%)

Measures adopted (no.)

Suppliers Ethic Agreement

For a shared business culture of integrity – legality

- Fighting public and private corruption.

- Rejecting all direct and indirect crimes against government, however they are committed.

- Fighting mafia infiltration into the legal economy.

- Protecting and safeguarding the environment to ensure sustainable development for future generations.

- Safeguarding workplace and construction site health and safety.

- Upholding the freedom of association and collective contracts, and preventing forced labour and the economic exploitation of minors.

- Complying with the principles of proper competition.

| Download XLS (25 kB) |

Suppliers (1) |

Number |

Employment practices (2) |

Environmental criteria |

Human rights (3) |

||||||||||||||

|

2013 |

2014 |

2015 |

2013 |

2014 |

2015 |

2013 |

2014 |

2015 |

2013 |

2014 |

2015 |

||||||

|

||||||||||||||||||

Goods |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Qualified suppliers |

1,538 |

1,472 |

867 |

36.7% |

37.9% |

44.4% |

36.7% |

37.9% |

44.4% |

100% |

100% |

100% |

||||||

of which A and B level |

262 |

227 |

160 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Suppliers qualified during the year |

71 |

129 |

56 |

35.2% |

25.6% |

60.7% |

35.2% |

25.6% |

60.7% |

100% |

100% |

100% |

||||||

of which A and B level |

9 |

17 |

10 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Works |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Qualified suppliers |

504 |

474 |

415 |

61.3% |

73% |

72.8% |

61.3% |

73% |

72.8% |

100% |

100% |

100% |

||||||

of which A and B level |

122 |

141 |

124 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Suppliers qualified during the year |

66 |

115 |

37 |

48.5% |

70.4% |

78.4% |

48.5% |

70.4% |

78.4% |

100% |

100% |

100% |

||||||

of which A and B level |

15 |

51 |

9 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Services |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Qualified suppliers |

3,163 |

2,391 |

1,819 |

38.6% |

41.9% |

36.8% |

38.6% |

41.9% |

36.8% |

100% |

100% |

100% |

||||||

of which A and B level |

235 |

269 |

218 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

Suppliers qualified during the year |

216 |

401 |

131 |

28.2% |

30.4% |

43.5% |

28.2% |

30.4% |

43.5% |

100% |

100% |

100% |

||||||

of which A and B level |

15 |

48 |

22 |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

100% |

||||||