HR2

Above all, sustainable management of the supply chain for Snam means conducting transparent relations with suppliers and, once the supply relationship is under way, involving them in the quest for long-term performance with a view to mutual growth and value creation.

Potential suppliers of goods and services to Snam must not only satisfy quality, price and reliability requirements, but also share enthusiasm for the sustainable innovation of processes and the search for ways to reduce impact on the environment and society throughout the supply chain.

Potential suppliers, especially of the most important goods, are therefore subjected to careful evaluation in order to determine whether they are likely to sustain the long-term relationship of trust that characterises Snam’s partnerships.

During their relationship with the Company, suppliers are constantly monitored by way of audits, inspections and service assessments. This is not only to ensure that their commitment to the agreements with Snam never waivers, but also to respond to their requests for assistance. A company’s conduct in terms of social and environmental responsibility is a key aspect of the service assessments.

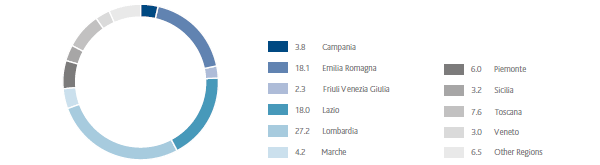

In 2012, Snam gave work to more than 1,000 companies in Italy and 50 elsewhere in the world, entering into 2,790 contracts worth a total of more than €1.4 billion. Of the orders, 97.6% were in Italy, where they were distributed throughout all the regions, 2.3% were in the rest of Europe and 0.06% were outside Europe.

EN1

The major goods category in 2012 was steel pipes for building natural gas pipelines, of which Snam acquired around 20,000 tonnes.

EC6

GEOGRAPHICAL BREAKDOWN PROCUREMENT IN ITALY (%)

LEGAL COMPLIANCE PROTOCOLS

After signing up to a voluntary agreement with the Caltanissetta prefectural authorities relating to the Gela region in 2012, Snam also continued to disseminate legal compliance protocols under the agreement between Snam Rete Gas and the Consorzio Stabile SIS Società Consortile per Azioni, relating to construction of the “Pedemontana Veneta” superhighway in Pedaggio, and the protocol signed between the Sicilian regional authorities, the regional office for energy and public utility services, the Italian Ministry of the Interior, prefectural authorities for the Sicilian provinces and Confindustria Sicilia. This experiment, carried out with the involvement of public and private partners, requires ethical conduct in relations between different parties, which is more restrictive than the legal requirements, ensuring sound oversight of the issue of lawfulness, to prevent the risk of corruption and promote the fight against organised crime, in support of fair, ethical and meritocratic local entrepreneurial development. By signing this document, Snam also made a commitment to ensure that its suppliers and sub-contractors also comply with its provisions, to efficiently prevent infiltration by organised crime.

THE VALUE OF TRANSPARENCY IN SUPPLIER RELATIONS

Snam has a transparent, impartial and responsible procurement policy which conforms to the principles of free competition and pays particular attention to local requirements, in line with the company’s strong roots throughout Italy.

These principles result in a carefully prepared management model which firstly identifies long-term performance and economic objectives as well as operating efficiency and service level targets.

The model then provides for specific procedures aimed at improving the process of scouting out new suppliers and guaranteeing that the selection process, during both the qualification and contract award stages, ensures equal opportunities for all once the required qualitative standards are met. In order to qualify for selection, potential suppliers must come through various preliminary evaluations, both theoretical and practical, according to the importance of the goods involved. To do this, Snam uses evaluation criteria which, taking into account order volume, financial scale, investments and operating cost analysis, classifies each supplier or product category precisely according to its importance in the Snam supply chain. The evaluation is performed with the systematic support of computer tools in order to ensure that the information gathered is traceable and comparable.

In 2012, there were 1,075 new qualifications or renewals. In total, 5,016 suppliers were qualified as at 31 December 2012, of which around 800 were classified as critical suppliers and responsible for more than 60% of Snam’s procurement.

In order to stimulate excellent and long-term performance among its suppliers, Snam monitors them continually by way of specific evaluations performed by the units responsible for managing the respective contracts. Around 600 feedback exercises were conducted in 2012 to monitor the performance of critical suppliers.

SUPPLIERS PORTAL

In the final months of 2012, Snam launched the first phase in the creation of the supplier portal, a web platform designed to be a single operational access point for managing suppliers. At the same time, the portal will be a useful tool in fostering dialogue with suppliers, including on sustainability themes, including: worker health and safety, human rights and respect for the environment and the regions. A systematic and structured information exchange is an opportunity to encourage reciprocal growth, business consolidation and joint reflection, providing real-time information, better communication, and “training” and information in a perspective of continuous development .

SUSTAINABILITY IN THE SUPPLY CHAIN

Snam pays close attention to managing economic, environmental and social risks relating to its suppliers. It does this particularly during the qualification stage for the most critical goods, the procedures of which have extremely stringent requirements; for example, the supplier must have certified management systems.

Snam requires all suppliers to be familiar with Model 231 and with the principles of its Code of Ethics, thereby ensuring that they comply with workplace safety, health and environmental protection regulations and with international standards on labour rights.

In 2012, Snam also extended its supplier accident index data collection to the supplier’s entire working cycle, rather than just their relationship with Snam. This was done to encourage more transparency and knowledge about the supplier and, where necessary, to start specific awareness-raising initiatives.

Lastly, in 2012 Snam group companies, by way of contractual documents, began a programme to raise supplier’s awareness and information of the UN Global Compact’s ten principles.

KEY PERFORMANCE INDICATORS (KPI)

| Download XLS (17 kB) |

|

KPI description |

KPI date |

Pre-set |

Target achieved |

Sector |

Activity |

|

Works suppliers (criticality A and B) ISO 9001 and ISO 14001 certified (%) |

2010 |

Achieve 100% by 2013 |

99 |

Snam group |

|