Snam for suppliers GRI - G4: EN1

Snam operates in supply chains in its own interest, transparently and in full respect of free competition, and seeks to involve suppliers in achieving long-term high levels of performance, with the aim of reciprocal growth and creating shared value. Its supply policy also includes a particular focus on supporting small - and medium - sized local enterprises, in keeping with the Company’s regional roots.

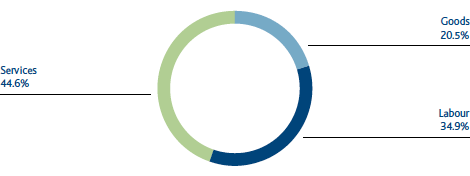

In what was one of the more difficult years for the economy and the national market in particular, Snam relied on more than 1,000 businesses, stipulating more than 1,600 supply contracts worth approximately €1.35 billion (€1.24 billion in Italy), divided between goods, labour and services.

Steel (tubing, fittings, etc.) accounted for the biggest proportion of the goods acquired by the Snam Group, with about 65,850 tonnes of supply recorded in 2013.

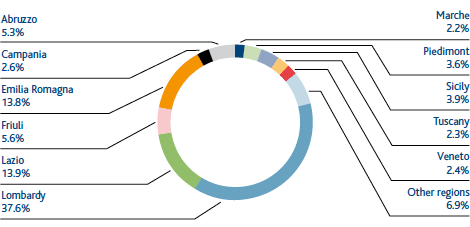

GEOGRAPHICAL DISTRIBUTION OF PROCUREMENT IN ITALY GRI - G4: EC9

PROCUREMENT BY NATURE OF GOODS

A clear and responsible relationship

Any parties intending to supply goods, labour and services to Group companies must not only meet its quality, price and reliability requirements but also share its drive towards innovating processes and its commitment to reducing environmental and social impacts and risks within the supply chain. This takes place through a rigorous and in-depth qualification process, which is the only way that the candidate supplier can enter into contact with Snam to showcase its current capacities and its future potential.

In order to qualify for selection, potential suppliers must come through various preliminary evaluations, both theoretical and practical, according to the nature and criticality of the goods involved. The evaluation is performed with the systematic support of computer tools in order to ensure that the information gathered is traceable and comparable.

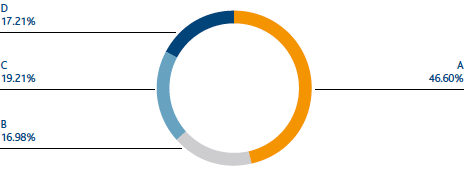

Goods are classified according to four levels of criticality (A, B, C and D) that are allocated to each group of goods according to their technological complexity and the impact on Snam’s performance. The A and B criticality classes represent the most critical level: more than 850 million of goods in these classes was procured in 2013 (amounting to some 63.6% of the total).

PROCUREMENT BROKEN DOWN BY CRITICALITY CLASS

Many elements are assessed, including technical and management capacity, economic and financial reliability, ethical profile (including for products), commitment to anti-corruption, safeguarding and protecting the environment, promotion of healthy and safe working conditions and the absence of forced or child labour. For the most critical goods, Snam’s procedures also include very stringent requirements, such as possession by the supplier of certified management systems compliant with international standards.

All 100% of critical suppliers, which represent about 14% of qualified suppliers, have certified quality and environmental management systems compliant with ISO 9001 and ISO 14001 standards.

| Download XLS (30 kB) |

|

Key performance indicators (KPI) |

|||||||||

|

|

|

|

|

|

|

||||

|

KPI description |

KPI date |

Pre-set target |

Target achieved in 2013 |

Sector |

Status of activities |

||||

|

|||||||||

|

Works suppliers (criticality A and B) |

2010 |

Achieve 100% by 2013 |

100 |

Snam Group |

|

||||

Snam requires all suppliers to show, through contractual documentation, that they are familiar with Model 231 and with the principles of its Code of Ethics, thereby ensuring that they comply with workplace safety, health and environmental protection regulations and with international standards on labour rights.

In 2013, 638 suppliers were involved in activities related to renewals and new qualifications. At year-end, a total of 4,565 suppliers were qualified.

The driver towards continuous improvement

The qualification process is part of the broader Vendor Management system, which also includes the monitoring of suppliers through audits, inspection visits and assessments of their services, prepared with the help of the units responsible for managing their contracts.

The system is designed to safeguard the integrity of the sustainability of the supply chain; Snam may place under observation, limit, suspend or even revoke the qualification of suppliers that fail to comply with the agreed standards. Possible failures include a lack of the technical and organisational requirements, negative assessments of the supplier’s services or those of its subcontractors, and failure to observe measures relating to regular contributions and the rules of Snam’s Code of Conduct.

In 2013, Snam carried out 21 audits on critical suppliers in the qualification phase, collected 941 feedback statements relating to 196 suppliers and issued 64 measures for non-fulfilment, including notices and qualification suspensions and revocations.

In 2013, the services assessment system was incorporated into a pilot project that introduced a points reward system for suppliers registering no accidents during execution of construction and maintenance activities on the gas infrastructure. Collection also began of the accident indices of suppliers throughout their working cycles, and not only as part of their relations with Snam. This was done to encourage more transparency and knowledge about the supplier and, where necessary, to start specific awareness-raising initiatives.

Finally, in 2013 Snam continued action to raise awareness of and disseminate the ten Global Compact principles among its suppliers.

| Download XLS (24 kB) |

|

Breakdown of suppliers according to sustainability issues |

||||||||||

|

|

|

|

|

|

||||||

|

Suppliers (1) |

Number |

Working practices (2) |

Environmental criteria |

Human rights (3) |

||||||

|

||||||||||

|

Goods |

|

|

|

|

||||||

|

Total qualified suppliers |

1,538 |

36.7% |

36.7% |

100% |

||||||

|

of which in criticality A and B classes |

262 |

100% |

100% |

100% |

||||||

|

Suppliers qualifying during the year |

71 |

35.2% |

35.2% |

100% |

||||||

|

of which in criticality A and B classes |

9 |

100% |

100% |

100% |

||||||

|

Labour |

|

|

|

|

||||||

|

Total qualified suppliers |

504 |

61.3% |

61.3% |

100% |

||||||

|

of which in criticality A and B classes |

122 |

100% |

100% |

100% |

||||||

|

Suppliers qualifying during the year |

66 |

48.5% |

48.5% |

100% |

||||||

|

of which in criticality A and B classes |

15 |

100% |

100% |

100% |

||||||

|

Services |

|

|

|

|

||||||

|

Total qualified suppliers |

3,163 |

38.6% |

38.6% |

100% |

||||||

|

of which in criticality A and B classes |

235 |

100% |

100% |

100% |

||||||

|

Suppliers qualifying during the year |

216 |

28.2% |

28.2% |

100% |

||||||

|

of which in criticality A and B classes |

15 |

100% |

100% |

100% |

||||||

The new supplier portal for sustainability

On 31 October 2013, Snam launched its new supplier portal, a web platform created as a single point of operational access to manage suppliers. In just two months of activity, about 350 users have also registered on the portal, and this number is expected to grow substantially in 2014.

The portal is designed to simplify and improve daily operations for everyone involved in managing the entire supply chain. It provides all potential interested suppliers with information about tender notices and qualification procedures, while active suppliers are provided with information, in a dedicated area, on the goods classifications for which they qualify, their active contracts, performance in terms of safety at work and all administrative items and forms.

The new portal is also designed to strengthen the dissemination of corporate social responsibility by exploring and sharing good practices on matters of central importance for Snam, including the health and safety of its workers, human rights and respect for the environment.