Water and waste management

Water consumption, water discharge and the production of waste are environmental aspects for Snam to be carefully managed, both from the perspective of quality and quantity, in order to reduce the associated environmental impacts. The Company started to develop a production cycle that is as circular and efficient as possible, improving performances in relation to the consumption of the resources used.

From the point of view of consumption, sea water and fresh water are used respectively in the production process and in company premises. In 2019, approximately 6.23 million cubic metres of water (6 million cubic metres of sea water and 0.23 million cubic metres fresh water) were extracted. The sea water was collected for cooling the auxiliary systems in the LNG plant and the same volume was discharged back into the sea, at a higher temperature (within the legal limits). The withdrawal was 51% higher than in 2018 following the increased operation of the plant equipment. Upstream storage activities produced approximately 6,159 cubic metres of process water (+4% compared to 2018), all sent to an external purification plant for treatment.

The extraction of fresh water, used mainly at the company premises activities, for fire-protection systems and to irrigate green spaces, increased by 70% compared to 2018. With regard to water discharges, the waste water is channelled into the sewage networks (42% of the total) or discharged, after treatment, into the soil and into surface water bodies (58% of the total).

The sites that cannot be connected to the sewerage system have closed-cycle phyto-purification systems, a technology that allows domestic waste water discharges to be eliminated because they are treated and fully absorbed by the planted vegetation.

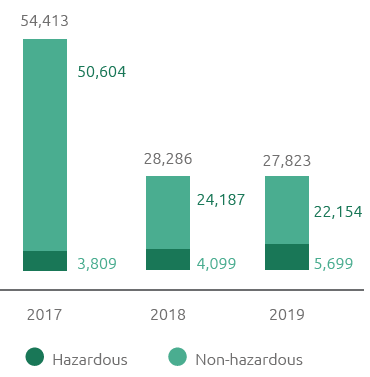

The production of waste comes mainly from plant maintenance and management activities (71%) and well drilling activities (29%). In 2019 the total production of waste stood at approximately 27,823 tonnes (-2% compared to 2018) of which more than 80% belonged to the non-hazardous waste category. 42% of waste from production activities was sent for recovery.

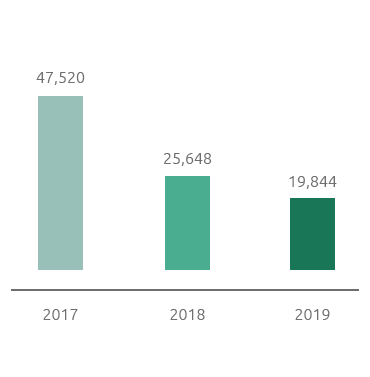

Freshwater procurement (103 m3)

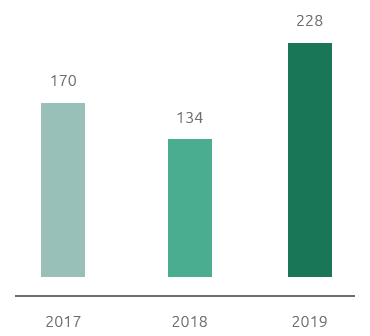

Freshwater discharge (103 m3)

Total waste production (t)

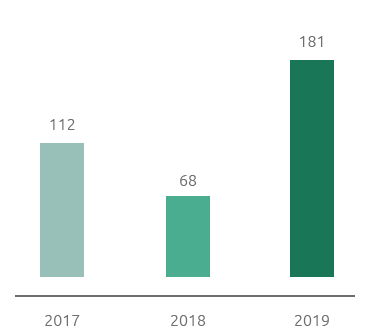

Waste by production activities (t)