Other environmental performance

Waste management

The waste that Snam produces can be traced mainly to three areas of activity: production, site reclamation and well drilling. Waste from production activities has always been a relatively insignificant environmental factor in terms of both the quantity and the type of waste. The waste generated derives mainly from the maintenance and management of the plants; the quantity produced also consists of ferrous materials, which are recovered in full.

Waste from reclamation activities results from the environmental requalification of 31 areas, with a total buildable area of around 135 hectares, contaminated as a result of earlier industrial activities, mainly due to the production of manufactured gas. Reclamation waste can also be produced during the laying of pipelines through contaminated sites not owned by Snam in which it must operate.

Waste deriving from well drilling consists mainly of slurries typically produced in some phases of the storage activity.

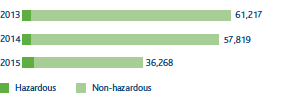

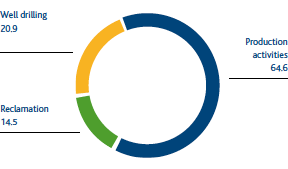

Total waste production was approximately 36,288 tonnes in 2015, down by 37% compared with the previous year. Out of the total waste produced, 91.4% belongs to the non-hazardous waste category and 8.6% to the hazardous waste category. 64.6% of waste was generated by production activities, 20.9% by well drilling and the remaining 14.5% by reclamation activities.

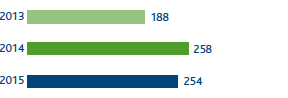

Waste generation (t)

Waste from production activies (t)

Waste generation by activity (%)

Again this year, Snam supported and actively participated in Let’s Clean Up the World, an initiative organised by Legambiente which in September involved thousands of people in cleaning up squares, gardens, parks, rivers and beaches throughout Italy.

Ecologically

The “Ecologically” project, launched in 2010, continued. This includes initiatives that aim to promote good eco-sustainable practices even in the office, with small daily gestures that help to improve the quality of the surrounding environment.

“All paper recycled” means making all personnel at all Group sites aware of the advantages of using recycled paper, whilst raising awareness of environmental protection issues.

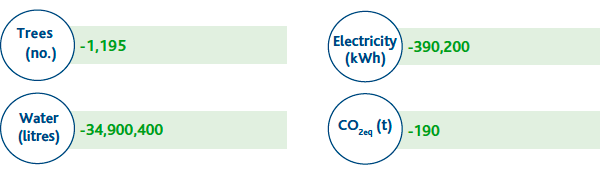

In 2015 the use of recycled paper with respect to total paper bought was 55%, allowing the Group to save natural resources and control carbon dioxide emissions.

The use of recycled paper in the company resulted in savings amounting to:

Water management

Water procurement and discharge in the activities of Snam represents a relatively insignificant environmental factor, in terms of both the quantities used and the type of discharges. In 2015, approximately 4.32 million cubic metres of water were procured (4 million of sea water and 0.32 million of fresh water). The procurement of sea water remains practically constant over time, as it is used for cooling auxiliary equipment in the LNG regasification plant. Fresh water procurement declined by 5% compared with 2014.

Fresh water is used primarily for office activities, fire-fighting apparatus and the irrigation of green spaces.

With regard to water discharges, the sea water is released into the sea as is, without any treatment, while the waste water is channelled into the sewage networks (68% of the total) or discharged, after treatment, into the soil and into surface water bodies (32% of the total).

To control the discharge of domestic waste water, 18 closed-cycle phyto-purification plants were installed over the years at corporate sites away from the sewage networks. These phyto-purification plants eliminate discharge since waste water is treated and fully absorbed by planted vegetation following the separation of sedimentable solids.

In the storage business, in the upstream phase, approximately 5,560 cubic metres of process water were produced. Of this water, about 2,238 cubic metres were reinjected as is, while the rest (about 3,322 cubic metres) was sent to a purification plant for treatment.

Fresh water procurement (103 m3)

Fresh water discharges (103 m3)