Supply chain integration GRI - G4: 12, EC9

Snam is a “vast” company that is deeply connected to its supply chain. In fact, suppliers of goods and services are increasingly an integral part of the business model, and they contribute to the creation of value since, in particular, they are directly involved in core development and maintenance processes for the infrastructure network.

Snam is guiding its suppliers to improve and optimise the ways they handle subcontracts to create greater responsibility on the part of subcontractors and ensure the growth of the supplier and better quality of the activities performed for the Company.

As a part of the dissemination of the sustainability culture, in July 2014 the third workshop was organised, this year at the Group level. The workshop was dedicated to “The Responsible Relationship between the Company and Supply Chain” focusing in particular on the sharing of information between the company and its suppliers, which is essential to enhance the sustainability culture and improve the best practices implemented by Snam and its suppliers.

SNAM AND ITS SUPPLIERS

A clear and responsible relationship

- Strive towards constant improvement and the achievement of long-lasting high levels of performance over time

- Not only quality, price and reliability requirements, but also a commitment to innovative processes

- Reducing environmental and social impacts and risks within the supply chain

- Reciprocal growth and creating shared value

- Dissemination and sharing of the values of legality, correctness, transparency and compliance with free competition

Snam Supplier Portal for sustainability

In 2013 Snam launched the Supplier Portal, a web-based platform designed to improve and optimise day-to-day operations of all those involved in the management of the entire supply chain. This tool provides information, best practices, downloadable documents, updates to procedures concerning the supplier qualification process, calls for bids, the procurement process and the e-business system.

At present about 1,000 suppliers are registered on the Portal. Each supplier is able to access, in the relevant private area, information on merchandise groups for which it is qualified, active contracts, performance in terms of work safety, all administrative elements and forms.

The Portal contains detailed information and good practices on issues of major importance for Snam including the health and safety of workers, human rights and respect for the environment.

During the year, several sections of the Portal were supplemented to continue to make it a useful tool for establishing a dialogue and sharing know-how with suppliers. In particular, the “Snam for Suppliers” section was created which includes the most significant data and indices concerning Snam’s procurement, and provides an additional contribution in terms of transparency and the completeness of information.

In 2014 over 83,000 visitors accessed the Portal 221,000 times and viewed over 800,000 pages (many sections of the Portal can be accessed without restriction).

Snam operates in supply chains in its own interest, transparently and in full respect of free competition, and seeks to involve suppliers in achieving long-term high levels of performance, with the aim of reciprocal growth and creating shared value. Its procurement policy also includes a particular focus on supporting small- and medium-sized local enterprises, in keeping with the Company’s regional roots.

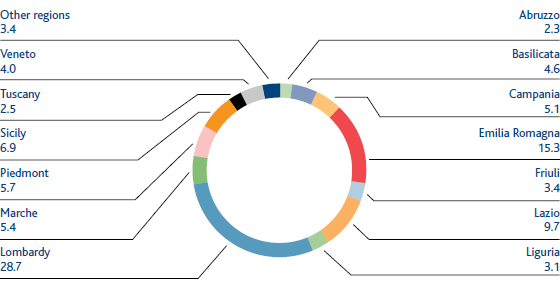

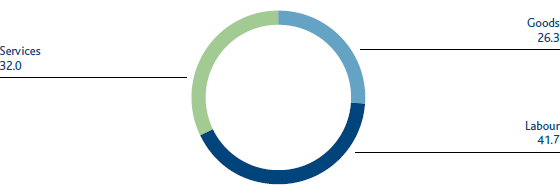

Faced with a severe economic crisis in the domestic market, in 2014 Snam put 970 companies to work including 628 small and medium-sized enterprises (SME), and it entered into 1,573 procurement contracts including 60% with SMEs for a total of €1.17 billion (92% in Italy) including goods, labour and services. Of the goods purchased, the most significant for the Snam Group is steel (pipes, pipe fittings, etc.), of which it purchased over 70,000 tons.

GEOGRAPHICAL DISTRIBUTION OF PROCUREMENT IN ITALY (%)

PROCUREMENT BY PRODUCT CATEGORY (%)

A clear and responsible relationship

Any parties intending to supply goods, labour and services to Group companies must not only meet its quality, price and reliability requirements but also share its drive towards innovating processes and its commitment to reducing environmental and social impacts and risks within the supply chain. This takes place through a rigorous and in-depth qualification process, which is the only way that the candidate supplier can enter into contact with Snam to showcase its current capacities and its future potential.

In order to qualify for selection, potential suppliers must come through various preliminary evaluations, both theoretical and practical, according to the nature and criticality of the goods involved. The evaluation is performed with the systematic support of computer tools in order to ensure that the information gathered is traceable and comparable.

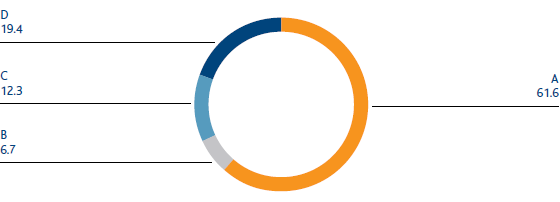

Goods are classified according to four levels of criticality (A, B, C and D) that are allocated to each group of goods according to their technological complexity and the impact on Snam’s performance.

Criticality categories A and B are the most critical level.

PROCUREMENT BROKEN DOWN BY CRITICALLY CLASS (%)

Many elements are assessed during the qualification process, including technical and management capacity, economic and financial reliability, ethical profile (including for products), commitment to anti-corruption, safeguarding and protecting the environment, promotion of healthy and safe working conditions and the absence of forced or child labour.

Suppliers are required to show, through contractual documentation, that they are familiar with Model 231 and with the principles of Snam’s Code of Ethics, thereby ensuring that they comply with workplace safety, health and environmental protection regulations and with international standards on labour rights.

For the most critical goods, procedures also include very stringent requirements for qualification such as the supplier’s possession of certified management systems compliant with international standards.

For example, 100% of suppliers in the “Labour” category with criticality levels of A and B (about 30% of qualified suppliers in the same category) have quality and environmental management systems certified according to ISO 9001 and ISO 14001 standards. Snam has set a goal for these suppliers to increase the holding of the OHSAS 18001 certification (health and safety of workers) through a specific KPI.

| Download XLS (29 kB) |

|

KEY PERFORMANCE INDICATORS (KPI) |

|||||

|

|

|

|

|

|

|

|

KPI description |

KPI date |

Pre-set target |

Target achieved in 2014 |

Sector |

Status Activities |

|

Number of labour suppliers (criticality levels A and B) with OHSAS 18001 certification |

2014 |

Achieve 90% by 2015 |

60 |

Gruppo Snam |

|

|

|

|

||||

During the year, 772 suppliers were involved in activities concerning renewals and new qualifications, and as at 31 December there were 3,641 qualified suppliers on the vendor list.

At 31 December 2014, Snam reported 22 pending disputes with suppliers. Of these, seven were initiated during the year, and 16 were closed in 2014.

The driver towards continuous improvement

The qualification process is part of the broader Vendor Management system, which also includes the monitoring of suppliers through audits, inspection visits and assessments of their services, prepared with the help of the units responsible for managing their contracts.

The system is designed to safeguard the integrity of the sustainability of the supply chain: Snam may place under observation, limit, suspend or even revoke the qualification of suppliers that fail to comply with the agreed standards. Possible failures include a lack of the technical and organisational requirements, negative assessments of the supplier’s services or those of its subcontractors, and failure to observe measures relating to regular contributions and the rules of Snam’s Code of Ethics.

In 2014, Snam carried out 19 audits on critical suppliers in the qualification phase, collected 1,042 feedback statements relating to 220 suppliers and issued 76 measures for non-fulfilment, including notices and qualification suspensions and revocations.

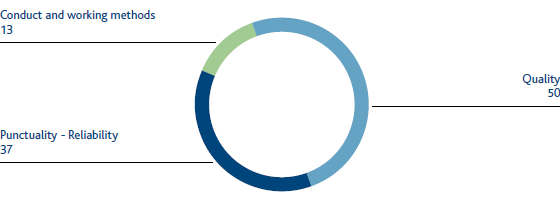

The Company’s policy includes the regular assessment of suppliers through the determination of a rating index (IR). The areas that contribute to determining this index concern the supplier’s ability to comply with technical contractual requirements as well as those relating to health, safety and the environment (Quality), meet delivery deadlines (Punctuality), and establish an excellent relationship with the principal during the entire term of the contract (Conduct).

RATING INDEX COMPOSITION (%)

As a part of the system to assess suppliers’ services, during the year the point reward system continued for suppliers reporting no accidents during the execution of construction and maintenance activities on the gas infrastructure.

Collection also continued of the accident rates of suppliers throughout their working cycles, and not only as part of their relations with Snam. This was done to encourage more transparency and knowledge about the supplier and, where necessary, to start specific awareness-raising initiatives.

Finally, the Company continued to make suppliers aware of the ten principles stated in the Global Compact and disclose these to them.

Based on the Company’s commitment to ensure that suppliers contribute to reducing environmental and social impacts and risks present in the supply chain, in 2014 the number of sustainability-related controls was increased.

Snam is committed to continuing in this direction, ensuring that the highest attention is paid to the analysis of the aspects associated with working practices, environmental criteria and human rights of all its suppliers.

| Download XLS (25 kB) |

|

BREAKDOWN OF SUPPLIERS ACCORDING TO SUSTAINABILITY ISSUES |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

Suppliers (1) |

Number |

Working practices (2) |

Environmental criteria |

Human rights (3) |

||||||||||

|

|

2013 |

2014 |

2013 |

2014 |

2013 |

2014 |

2013 |

2014 |

||||||

|

||||||||||||||

|

Goods |

|

|

|

|

|

|

|

|

||||||

|

Qualified suppliers |

1,538 |

1,472 |

36.7% |

37.9% |

36.7% |

37.9% |

100% |

100% |

||||||

|

of which in criticality classes A and B |

262 |

227 |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

|

Suppliers qualified during the year |

71 |

129 |

35.2% |

25.6% |

35.2% |

25.6% |

100% |

100% |

||||||

|

of which in criticality classes A and B |

9 |

17 |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

|

Labour |

|

|

|

|

|

|

|

|

||||||

|

Qualified suppliers |

504 |

474 |

61.3% |

73% |

61.3% |

73% |

100% |

100% |

||||||

|

of which in criticality classes A and B |

122 |

141 |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

|

Suppliers qualified during the year |

66 |

115 |

48.5% |

70.4% |

48.5% |

70.4% |

100% |

100% |

||||||

|

of which in criticality classes A and B |

15 |

51 |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

|

Services |

|

|

|

|

|

|

|

|

||||||

|

Qualified suppliers |

3,163 |

2,391 |

38.6% |

41.9% |

38.6% |

41.9% |

100% |

100% |

||||||

|

of which in criticality classes A and B |

235 |

269 |

100% |

100% |

100% |

100% |

100% |

100% |

||||||

|

Suppliers qualified during the year |

216 |

401 |

28.2% |

30.4% |

28.2% |

30.4% |

100% |

100% |

||||||

|

of which in criticality classes A and B |

15 |

48 |

100% |

100% |

100% |

100% |

100% |

100% |

||||||