Other environmental impacts

Waste management

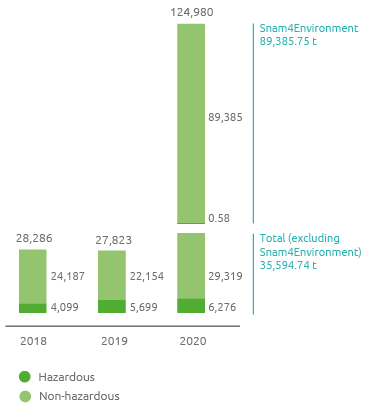

Total waste production (t)

For Snam, proper waste management is an environmental aspect that needs to be carefully managed and monitored, even though it is not a significant issue either in terms of the amount of waste produced or its type, since most of it is primarly made up of non-hazardous ferrous waste, which is fully recovered. In fact, in Snam’s operations, waste production is mainly attributable to three macro-activities: plant maintenance and management (86%), reclamation during pipeline laying (7%) and well drilling (7%).

In order to effectively manage waste production, Snam is committed to developing a production cycle that is as circular as possible, and which allows waste to be transformed into a resource for reuse wherever possible. For example, the plants of Renerwaste, a subsidiary of Snam4Environment, combine the need for urban waste disposal with the recovery of materials and energy, promoting the valorisation of depleted landfills and the conversion of composting plants from aerobic to anaerobic.

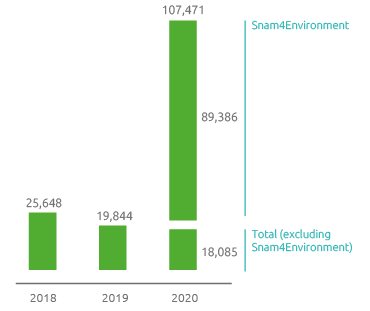

Waste from production operations (t)

In 2020, total waste production amounted to 124,980 tonnes, showing a sharp increase compared to 2019 mainly due to the inclusion of Snam4Environment in the scope of consolidation, which was responsible for the production of 89,386 tonnes of waste (71.5% of the total). The 95% of the waste produced belongs to the non-hazardous waste category and 32% of the waste from production activities was sent for recovery.

Water management

Snam’s water procurement and disposal activities are an irrelevant environmental aspect, both in relation to the quantities used and the type of withdrawals and discharge. However, the Company considers water a primary resource that should be conserved and in that respect it is committed to keeping down its consumption and reducing its environmental impacts.

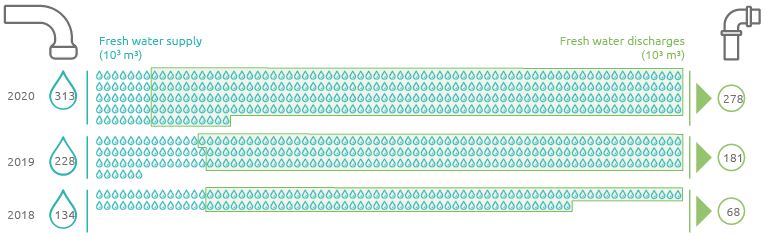

Sea water and fresh water are used in the production process and offices respectively, resulting in total consumption of approximately 6.36 million cubic metres in 2020 (6.05 million cubic metres of sea water and 0.31 million cubic metres of fresh water).

Sea water is taken for the cooling of auxiliary plants at the Panigaglia LNG plant in Liguria, and is completely discharged into the sea in the same volume, with a higher temperature value (within the terms of the law). The withdrawal is in line with that had in 2019 and compared to 2018, increased by 33% as a result of increased operation of plant equipment. The upstream storage activities produced approximately 6,050 cubic metres of process water (-1.8% compared with 2019), all sent to an external treatment plant for treatment.

The withdrawal of fresh water, mainly used for office activities, fire-combating systems and irrigation of green areas increased by 37% compared to 2019, while with regard to water discharges, wastewater is either conveyed to the sewerage system (78% of the total) or discharged, even after treatment, into the soil and surface water bodies (22% of the total). In sites that do not have the possibility of being connected to the sewage system, closed-loop phyto-purification plants have been installed, a technology that makes it possible to eliminate the discharge of domestic wastewater, as it is treated and entirely absorbed by the planted vegetation.

Water (103 m3)