Energy consumption

Snam’s main energy consumption is due to the energy needed to operate the gas turbines used in the storage plants and those present in the compression plants, which provide the pressure needed to transport the gas along the national network. The energy used depends both on the amount of gas transported and on the point of entry into the national grid, which influences the route the gas must take to reach the distribution points and therefore affects the energy requirements of transport.

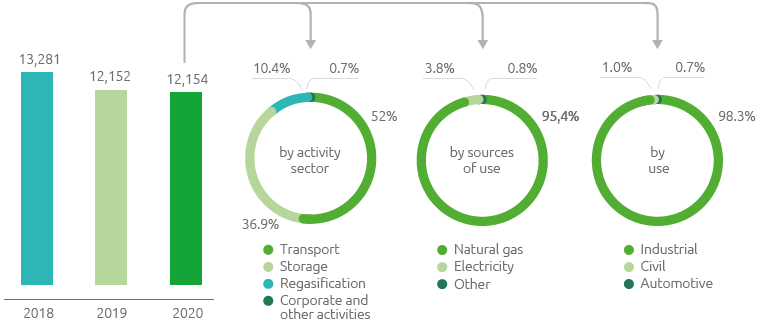

In 2020, energy consumption totalled 12,154 TJ (+0.02% in line with 2019). The energy mix is almost entirely composed of natural gas (95.4%), which is used for the operation of transport, storage and regasification plants, for heating buildings and for transport. The other sources used are electricity (3.8%), which is needed mainly for the operation of industrial sites, as well as for lighting and heating/air conditioning in offices and servers. Other fuels (diesel, gasoline, LPG) and heat, which together account for 0.8% of total energy consumption, are used for plant operation, heating and as fuel for the company fleet.

The trend in energy consumption in 2020 was strongly influenced by the activities of the core business: in the case of gas transportation, the use of more energy-intensive import backbones (North Africa backbone), compared to less energy-intensive ones (Northern Europe and Russia backbones), led to an increase in consumption, despite there being a reduction in gas injected into the network (-7% compared to 2019). As regards the regasification business, the increase in the amount of regasified gas led to an increase in the consumption of the regasification plant (+4% compared to 2019) and a simultaneous reduction in consumption for storage (-6% vs. 2019), in line with the reduction of gas stored.

Energy consumption (TJ)